セラミック絶縁放熱基板

セラミック絶縁放熱基板は、電子デバイスや効果的な放熱が必要なその他の用途に使用される特殊なタイプのセラミック基板です。これらの基板は通常、高温に耐え、熱伝導率が高いことで知られる窒化アルミニウム、炭化ケイ素、アルミナなどの材料で作られています。 最新の販売、低価格、高品質のセラミック絶縁放熱基板を購入するために当社の工場に来ていただくことを歓迎します。トルボはあなたとの協力を楽しみにしています。

お問い合わせを送信

Ceramic insulating heat dissipation substrates

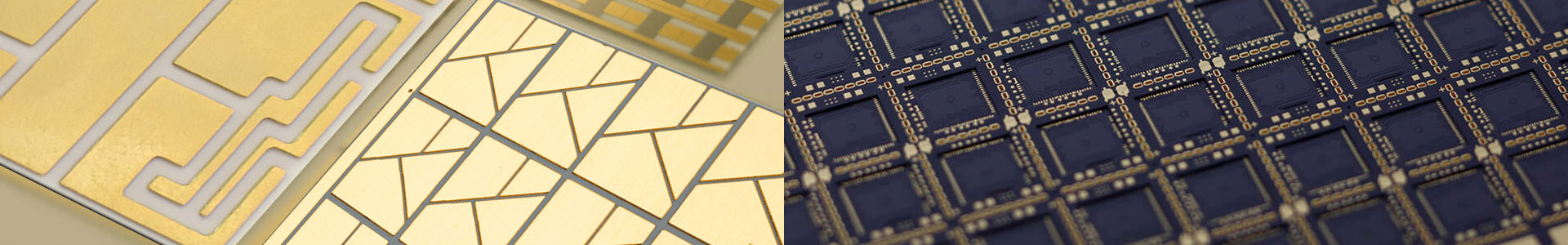

Ceramic insulating heat dissipation substrates are a specialized type of ceramic substrate used in electronic devices and other applications that require effective heat dissipation. These substrates are typically made of materials such as aluminum nitride, silicon carbide, or alumina, which are known for their ability to withstand high temperatures and high thermal conductivity.

The primary function of ceramic insulating heat dissipation substrates is to dissipate heat generated by electronic components such as power semiconductors and light-emitting diodes (LEDs). The substrates are designed to provide excellent thermal conductivity, enabling efficient heat transfer from the electronic components to the surrounding air or cooling system. The ceramics used in these substrates are highly insulating, which means they provide exceptional electrical insulation properties, protecting the electronic components from damage due to electrical overload or short circuits.

Ceramic insulating heat dissipation substrates are popular in various industrial applications, including automotive electronics, power electronics, aerospace, and LED lighting. They are preferred over other materials, such as plastics or metals, for their superior thermal conductivity, electrical insulation, and durability. The high thermal conductivity of these substrates also ensures that there is less thermal stress on both the electronic components and the substrate material, which improves reliability and performance.

Overall, ceramic insulating heat dissipation substrates offer excellent performance and reliability in electronic applications that require effective heat dissipation, high thermal conductivity, and electrical insulation.

You can rest assured to buy customized Ceramic insulating heat dissipation substrates from us. Torbo look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

Item:Ceramic Insulating Heat Dissipation Substrates

Material:Si3N4

Color:Gray

Thickness:0.25-1mm

Surface processing:Double polished

Bulk density: 3.24g/㎤

Surface roughness Ra: 0.4μm

Bending strength: (3-point method):600-1000Mpa

Modulus of elasticity:310Gpa

Fracture toughness(IF method):6.5 MPa・√m

Thermal conductivity: 25°C 15-85 W/(m・K)

Dielectric loss factor:0.4

Volume resistivity: 25°C >1014 Ω・㎝

Breakdown strength:DC >15㎸/㎜